Detailing Solutions

Elevate your vehicle's appearance and retail value with expert car detailing services at Graham Rahal Performance. Our detailing solutions encompass thorough cleaning and restoration of both the interior and exterior, ensuring a comprehensive enhancement of your car's overall aesthetics. Discover the premium detailing services that can rejuvenate your vehicle and leave it looking its best. Trust Graham Rahal Performance for top-notch car detailing tailored to meet your automotive needs

- Car Wash

- Interior Detail

- Underbody Wash

- Dry Ice Leather Conditioning

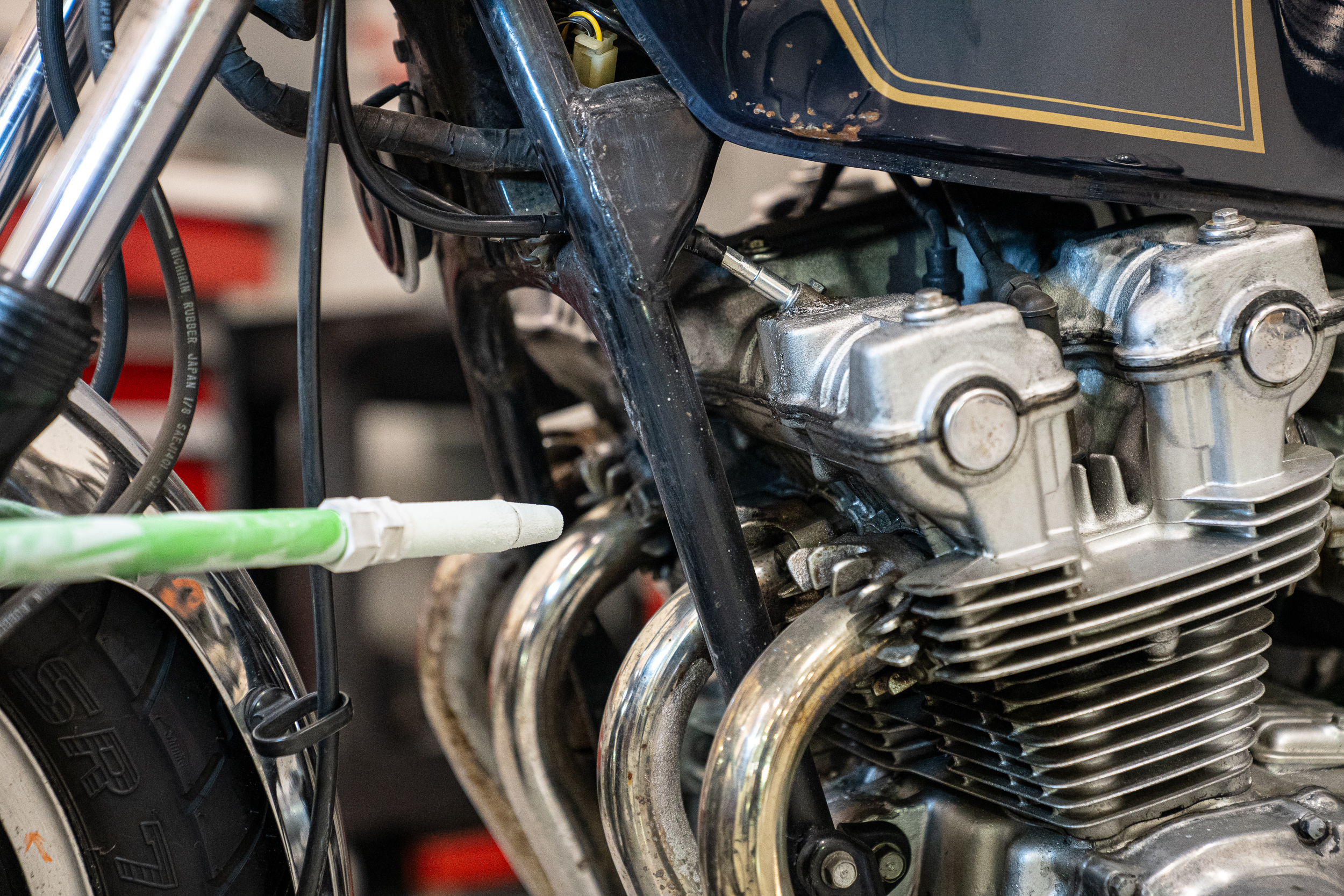

- Engine Detail

- Vapor Honing

Dry ice blasting involves propelling small pellets of dry ice (solid carbon dioxide) at high speeds to clean surfaces. This cleaning method is non-abrasive and can be effective for removing contaminants, grease, paint, and other residues from different materials without causing damage. In the automotive industry, dry ice blasting is sometimes used to clean engine components, machinery, and other automotive parts.

Benefits of Dry Ice Blasting for Vehicles:

- Non-Abrasive: Dry ice blasting is non-abrasive, meaning it won't damage the surfaces being cleaned. This is particularly useful for delicate components and sensitive materials in vehicles.

- Environmentally Friendly: Dry ice sublimates (converts from a solid to a gas) upon contact with the surface, leaving no secondary waste. It is a more environmentally friendly cleaning method compared to some traditional methods that may involve chemicals.

- No Residue: Dry ice blasting leaves no residue since the dry ice pellets sublimate, resulting in a cleaner surface without the need for additional cleanup.

- Efficient: It can be a fast and efficient method for removing stubborn contaminants, making it suitable for various automotive cleaning applications.

Vapor honing, also known as vapor blasting or wet blasting, is a surface finishing process that utilizes a mixture of water, abrasive media, and compressed air to clean, deburr, and enhance the appearance of surfaces. When applied to vehicles, vapor honing can offer several benefits:

- Gentle Cleaning: Vapor honing is a relatively gentle process that effectively removes contaminants, dirt, grease, and oxidation from various surfaces without causing damage. It is suitable for delicate components and materials.

- Surface Restoration: The process can restore the original finish and appearance of automotive components, including engine parts, wheels, and other metal or non-metal surfaces. It helps bring back the luster and shine.

- Deburring and Descaling: Vapor honing is effective in removing burrs, scale, and other imperfections from metal surfaces. It can improve the overall quality and functionality of automotive parts.

- Consistent Finish: The process provides a uniform and consistent finish across the entire surface. This can be particularly important for components that require a smooth and even appearance.

- Versatility: Vapor honing is versatile and can be used on a variety of materials, including aluminum, steel, plastic, and more. It is suitable for cleaning and refinishing different automotive parts.

- Environmentally Friendly: Compared to some other abrasive cleaning methods, vapor honing is considered more environmentally friendly. It typically uses less abrasive media and generates less waste.

- Less Abrasive Impact: Vapor honing is generally less aggressive than traditional blasting methods, making it suitable for components that require a softer touch to avoid damage or distortion.

- Paint Preparation: Vapor honing can create a surface that is ideal for paint adhesion. It removes contaminants and provides a clean, slightly textured surface, improving the bond between the substrate and paint.

- Reduced Dust and Airborne Particles: The addition of water in vapor honing helps to suppress dust and airborne particles, creating a cleaner working environment and reducing the risk of respiratory issues for operators.

- Enhanced Corrosion Resistance: By removing contaminants and imperfections, vapor honing can contribute to improved corrosion resistance on metal surfaces, extending the lifespan of automotive components.